Features

1. 20 high-speed dental ceramic bearings for NSK high-speed handpiece

2. High-precision miniature bearings used 9Cr18 stainless steel inner and outer rings (stainless steel) Materials made by precision machining.

3. Precision bearings to achieve Level P4 level (ABEC7 level) tolerance precision, superhard ceramic (Si3N4) ceramic ball materials produced for the Japanese ASK, ceramic bowls are self-steel bowls of 30% -40%, can be 4. reduced due to the centrifugal force generated by the increase in dynamic and skidding load.

5. Because of high wear-resistant, American origin Torlon PAI (Polyamide - imide resin), 80 ~ 120 cloth phenolic bakelite material.

6. Cage has a high temperature, anti-abrasion, low friction, high strength, such as outstanding performance.

7. High-speed micro-dental bearings have high-speed (up to 35 - 45 ten thousand rev / min), low noise, low friction torque, long service life, etc.

8. Ceramic bearings with high temperature, cold, wear resistance, corrosion resistance, anti-magnetic electric insulation, oil-free self-lubricating, and other characteristics of ultra-high speed.

9.Can be widely used in aviation, aerospace, marine, petroleum, chemicals, and medical equipment, scientific research and national defense and military fields, the application of new materials are high-tech products can be used in extremely harsh environment.

Specifications

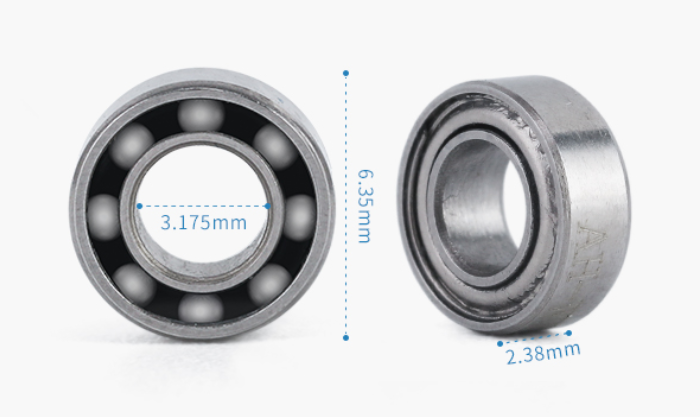

Interior diameter:3.175mm

Exterior diameter:6.350mm

Thickness:2.380mm

The use of air pressure: 200-250Kpa

Bearing Noise: Less than 68dB

商品に関するお問い合わせ